Welded Steel Bar Grating

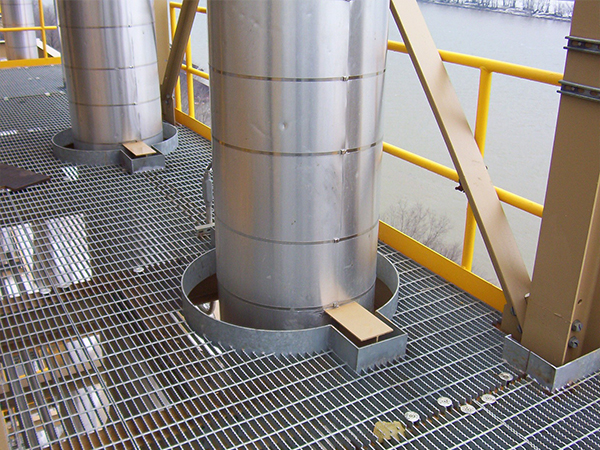

For more than 10 years, Enzar Metal has been manufacturing Welded Steel Bar Grating and provides superior solutions to engineer and architects challenged with specifying the ideal industrial flooring, security or processed application products to all over the world. Welded Steel Bar Grating is the most popular of all grating types due to its strength, cost efficient production and easy installation. Widely used in most general industrial facilities as well as commercial buildings, it has numerous applications such as walkways, platforms, safety barriers, drainage covers, and so on.

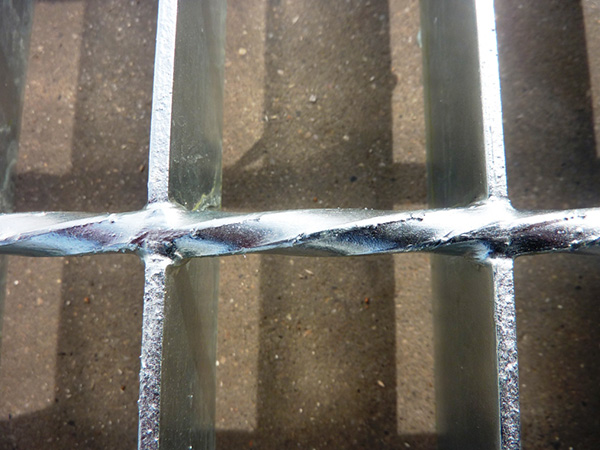

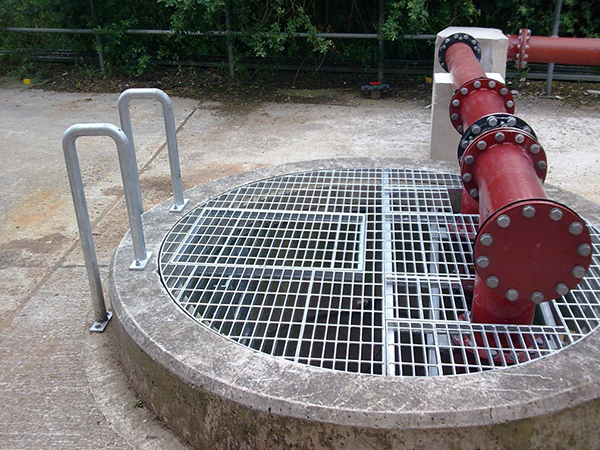

Bar Grating consists of a series of bearing bars welded at various spacing to perpendicular cross bars to build a load-bearing panel. Typical panel configuration has bearing bars that are spaced 30mm (center to center) with perpendicular cross bars spaced 100mm apart (center to center). Other spacings are available to meet your loading and open area requirements. Uses include ground mats and transformer pit covers for the electrical substation industry; trench grating covers for the automotive industry; walkways for aggregate conveyor systems; wet drainage applications at poultry plants and wastewater facilities.

Manufacturing Machines & Processing

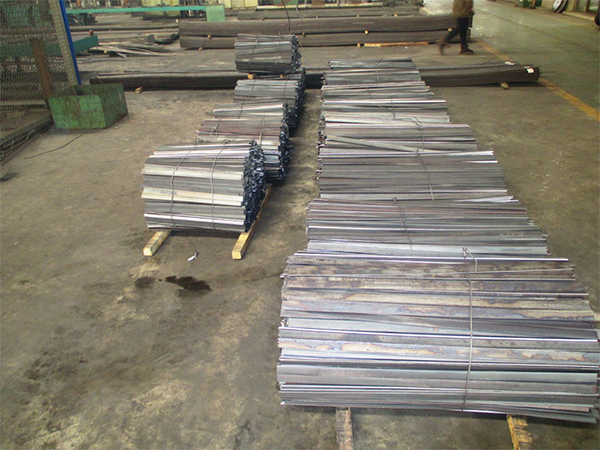

Raw Materials

In our warehouse, we stock a huge volume of flat bars, sheet metal and wire rods ready for steel bar grating manufacturing. This situation challenges our capacity of cash flow, but it significantly helps us in reacting to order process performance and give firm promise to quality assurance.

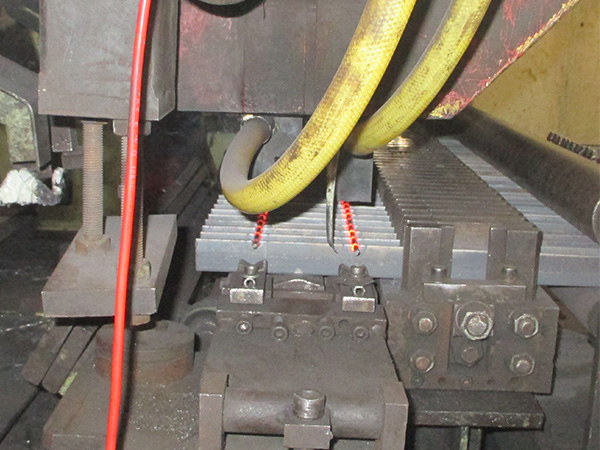

Fused Press Welding Machines

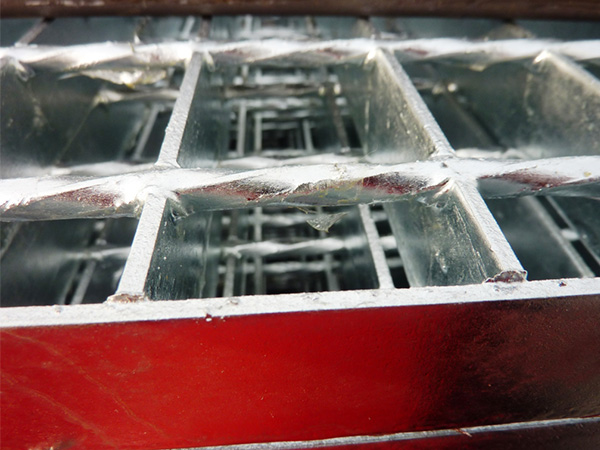

Welded steel bar grating is the most common available grating type on the market. It is manufactured by a fused welding process. Crossbars are fused and pressed to bearing bars to form a permanent joint. They are economical, yet durable for most applications. In Enzar Metal, we have 5 sets of fused press welding machines along with a series of twisted bar drawing machines, flat bar shearing machines, cutting & sawing machines and spot welding work bench, which means five lines of manufacturing systems are ready for producing high quality products anytime for your order. Our max. production capacity can reach 100 tons per day.

Hot Dipped Galvanized Treatment

We are running HDG workshop with strong capacity for our bar grating and other steel and mesh products. We work excellent in both environment protection and products quality.

Warehouse & Packing

We carry large stock of welded steel bar grating in various specifications. Specially, some of the stock is unfinished in black. HDG process will be processed instantly for shipping.

Common Specifications with charting

| Standards |

Steel Grating Standard |

Steel Material Standard |

HDG Coating Standard |

| China |

YB/T4001-1998 |

GB700-88 |

GB/T13912-92 |

| USA |

ANSI/NAAMM(MBG531-88) |

ASTM-A36 |

ASTM-A123 |

| UK |

BS4592-1987 |

BS4360(43A) |

BS729 |

| Australia |

ASl 657-1992 |

AS3679 |

ASl650 |

All our products are equivalent or exceeds major international standard. We follow the standards in our manufacturing and processing as below.

| Parameters |

Data |

| Bear Bar Type |

Flat Bar, I-Bar, Serrated Bar, etc.. |

| Bearing Bar Size |

20x5mm, 25x3mm, 35x5mm, 40x5mm, 50x5mm, 60x5mm, etc.. |

| Bearing Bar Spacing |

20mm, 25mm, 30mm, 33mm, 40mm, 43mm or multiplier. |

| Cross Bar Type |

Twisted Steel Rod, Flat Bar |

| Cross Bar Size |

3mm, 4mm, 5mm ,6mm or thicker |

| Cross Bar Spacing |

50mm or 100mm |

| Bearing Bar Length |

Customerized from 1000mm to 6000mm or more |

| Cross Bar Length |

Under 1200mm |

| Material Grade |

Mild Steel(Q235B), Stainless Steel 304 or 316, etc. |

| Treatment Available |

Hot dipped Galvanized, Anodized, Polished and Powder Coated |

Frame & Installation & Fixing

Bar Grating Fixing

Welded Steel Bar gratings can be installed in two methods: Welding is advisable for permanent use free of removing/dismantling. Bar Grating will be welded to the supporting frame (angle steel, I steel or other structural steel) at each corner. Fillet weld is required when weld length more than 20mm and height more than 3mm.

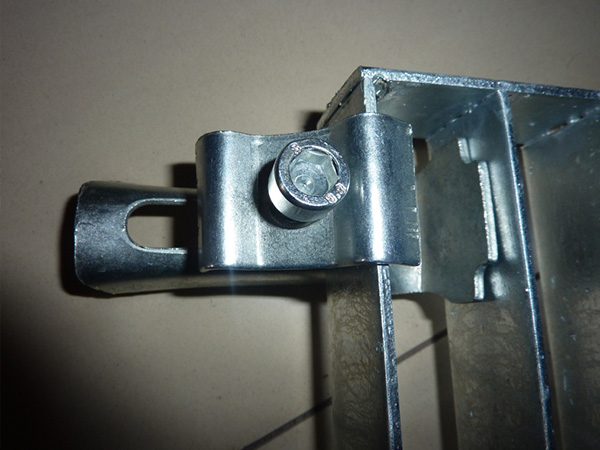

Installation Clips will not destroy the zinc coating and be easy to remove. Each panel requires at least four installation clips. For the larger panels preferably some more clips are needed to fix to the proper support frame.

Installation Frames

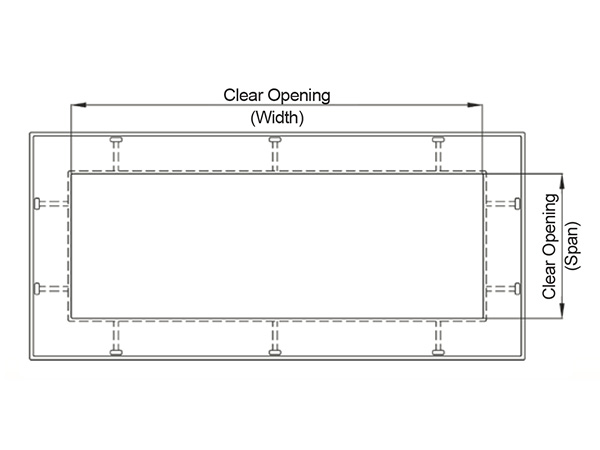

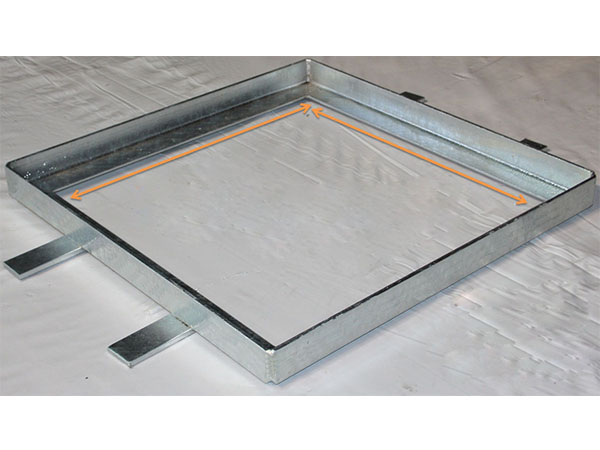

Frames provide a uniform bearing surface for all our grating products and help eliminate the potential for rocking or irregular elevations experienced when only covers are installed on poured concrete. All frames are available in four sided in one piece made of angle steel and processed with regular treatment, like HDG.

Assortments & Applications of Welded Steel Bar Grating

Walkways & Ramps

Enzar Metal welded steel bar grating is used for walkways, platforms and stairways, providing safe access solutions in any industry.

Stairways & Stair Tread

Enzar Metal stair treads are made from our high-quality fused press welded bar grating and fabricated by excellent workmanship. Please send your specific requirements to us about your stair tread demand. Various tread types and sizes are available from us, which are equivalent to webforge stair treads T1, T2, T3, T4, or etc..

Platform & Flooring

Enzar Metal bar grating provides a safe working surface that allows light and air to penetrate in process or treatment plants, on platforms, around air conditioning systems and for any application where maintenance access is required. It can be also used as commercial and industrial flooring material in some certain applications.

Safety Fencing Barrier

Bar grating fence is another stronger way comparing to wire mesh fence, even it has no advantage in pricing.

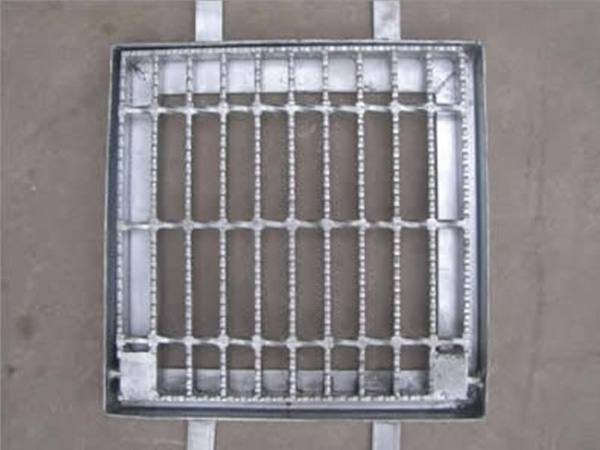

Drainage Cover

In both industrial and commercial drainage system, bar grating is widely applied. We are also capable of some special design in stainless steel material for indoor usage, which requirements are more critical and needs better surface finishing.

Tree Guard

Bar Grating is the regular material to protect the soil around trees.