Perforated Sheet

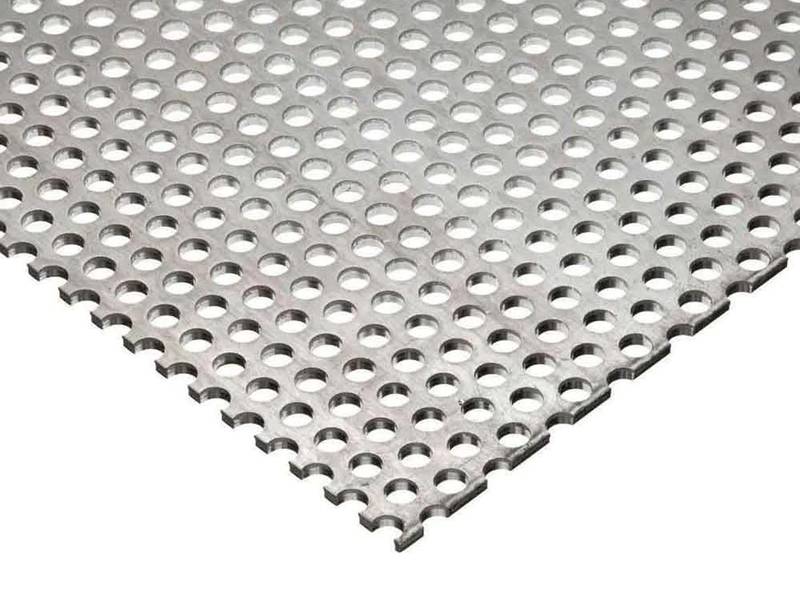

Perforated sheet used mild carbon steel, stainless steel, aluminum steel as raw material to be punched with round, square or decorative holes in a uniform pattern. Perforated sheet has various applications.

Material of the perforated sheet

Perforated sheet is made of different materials, and each one has its own features, you can choose the perfect one for you.

Mild carbon steel perforated sheet. It is the most economical materials. Mild carbon steel perforated sheet can improve the long life through galvanized surface treatment (hot-dipped or electric galvanized). The different color of powder coated or painted can let sheet colorful and durable.

Aluminum perforated sheet. It is lightweight than other materials of perforated sheet, and it need minimized maintenance.

Stainless steel perforated sheet. It is the most durable among the materials. Stainless steel is resistant to the corrosive, weather, acid, rust and other chemical actors.

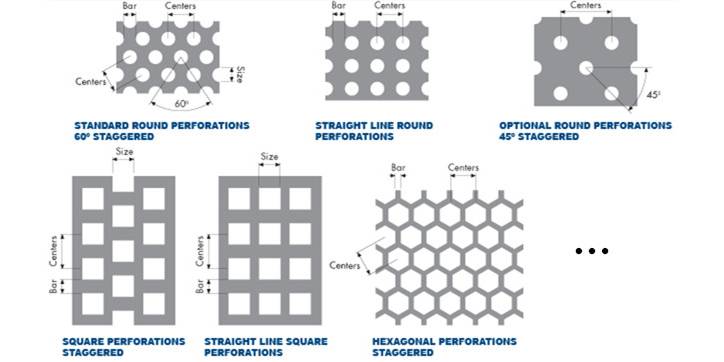

Hole type of the perforated sheet

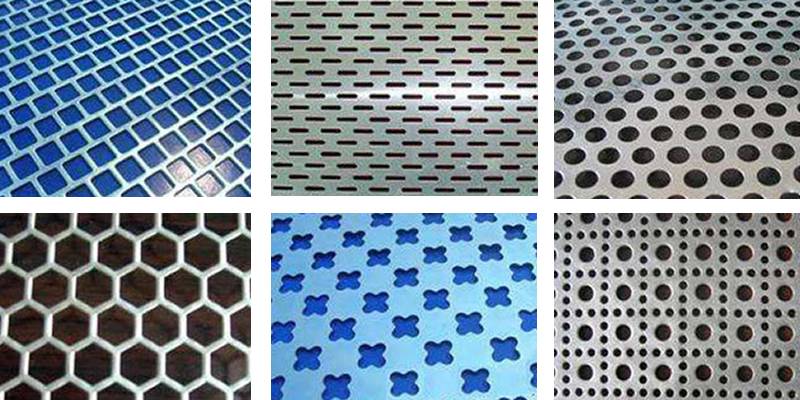

Hole types of the perforated sheet is various, we cannot calculate the accurate quantity of it. There are five main category of it.

Round hole is the most commonly used hole type. It can be used in each application of the perforated sheet.

Square hole and hexagonal hole can be used in the vibrating screen.

Slotted hole can be used in the perforated filter pipe.

Decorative holes can be used single or combine to form various beautiful designs for interior and exterior designs.

Common Specifications

- Material: Mild carbon steel, Aluminum, Stainless steel…

- Hole Type: Round hole, square hole, hexagonal hole, decorative hole…

- Thickness: 0.5mm - 5mm.

- Hole Size: 3mm – 12mm

- Hole Center: 3mm - 200mm

- Hole Pattern: Staggered or straight row.

- Surface Finish: Mill and powder coated.

- Percent Open Area: 23%, 30%, 33%, 40%, 41%, 42%, 48%, 51%.

- Width: 0.5m – 3m.

- Length: 0.5m – 3m.

| Hole Size |

Hole Center |

Hole Pattern |

Thickness(Gauge) |

Open Area |

| 1/16" |

1/8" |

Staggered / straight row |

22 |

23% |

| 3/32" |

5/32" |

Staggered / straight row |

22, 16, 12 |

33% |

| 3/32" |

3/16" |

Staggered / straight row |

22, 20, 18, 16 |

23% |

| 1/8" |

3/16" |

Staggered / straight row |

22, 18, 16, 14 |

41% |

| 1/8" |

7/32" |

Staggered / straight row |

22, 16, 14 |

30% |

| 3/16" |

1/4" |

Staggered / straight row |

20, 18, 16 |

51% |

| 1/4" |

3/8" |

Staggered / straight row |

16, 12 |

42% |

| 3/8" |

1/2" |

Staggered / straight row |

22 |

51% |

| 3/8" |

9/16" |

Staggered / straight row |

16, 12 |

40% |

| 1/2" |

11/16" |

Staggered / straight row |

22, 16, 12 |

48% |

| If you have other request, please let us know, we can receive customized specifications. |

Production process of the perforated sheet

Packaging of the perforated sheet

Perforated metal appears in roll type and flat type. They are packed in Pallet or with plastic film or according to customer requirements.

Feature of the perforated sheet

- Net formation face is smooth, beautiful, sturdy and durable; there are a wide range of uses.

- Can be readily formed, easy installation

- Can be painted or polished and anodizing.

- Large selection of hole size patterns and configurations

- Uniform sound abatement(aluminum perforated metal)

- Attractive appearance and durable

Application of the perforated sheet

Perforated sheet is widely used in the daily life, food industries, pharmaceutical industries, water, oil filtration industries, architecture and many other areas. Just see which one is fit for you.

- Protective perforated sheet. It can be categorized to perforated sheet fencing & gate, balustrade & balcony and sunshade screen. It can supply the full protection in our daily life.

- Decorative perforated sheet. Various decorative hole types and patterns can provide the aesthetic sense for the buildings, malls and other interior and exterior designs.

- Wind dust net. It can control the dust pollution through controlling the wind moving. It is widely used in the ports, power generation, coal, coke, iron steel and other business fields.

- Noise barrier. Noise barrier is also called sound barrier. It has two hole types of louvers and round. With different materials and sheet types, noise barrier can reduce and absorb the noise caused by the vehicles, air conditions and machinery.

- Perforated vibrating screen. It is the best choice in unique and severe screening situation sand for specified screening application and screening equipments.

- Perforated filter pipe. It can be divided into bridge slotted screen and perforated pipe. It is commonly used in exhaust system; filtration systems, aerospace, paper & pulp, petrochemical, oil and gas, and so on.

- Speaker grills. Perforated sheet speaker grill has small hole size to filter the sound and protect the device. It is used in the automobile speakers, bluetooth speakers and other sound equipments.

- Anti-slip perforated sheet. Anti-slip perforated sheet has two kinds - embossed surface and safety grating. They can prevent people from sliding and protect the safe. It can be used as stair treads, workplace platforms and other places.