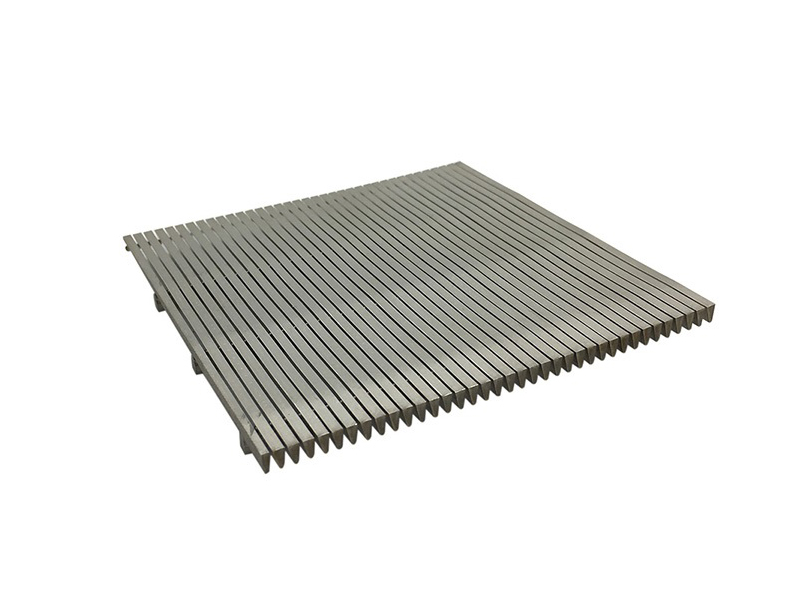

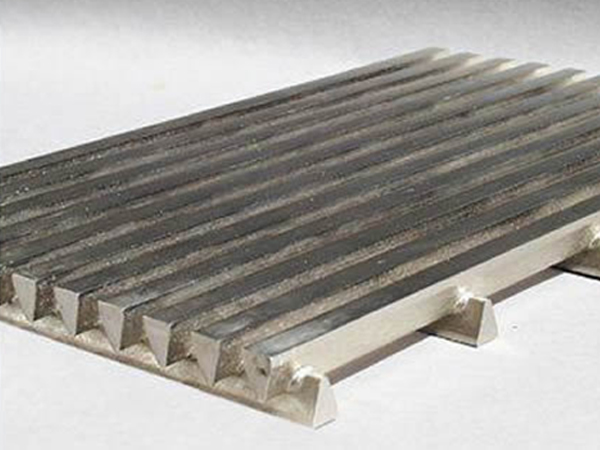

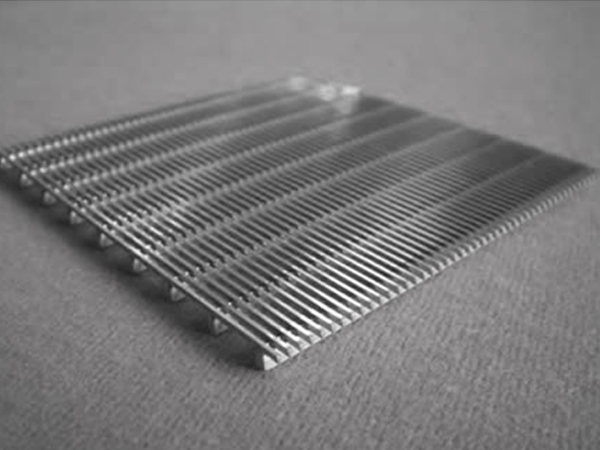

Rectangular Bar Support Profile.

+86-13722829512

- Home

-

Products

-

Metal Fence

- Peach post

- Crowd Control Barrier

- Windbreak Panels

- Bird Spikes

- Wall Spike

- Arch top Garden Fencing

- Double Loop Fence

- Euro Fence

- Prestige Wire Mesh Fence

- Razor Wire

- Barbed Wire

- Palisade Fencing

- Brc Fence

- Australia Temporary Fence

- Fixed Knot Fence

- Field Fence

- Y Post for Field Fence

- Double Wire Fence

- Curvy Fence Panel

- 358 High Security Fence

- Chain Link Fence

- Steel Grating

- Gabion Mesh

- Wire Mesh Rolls

- Welded Wire Mesh Panel

- Expanded Metal

- Chicken Coops & Dog Kennel

- Mesh Filter / Filter Elements

- Decorative Mesh

- Perforated Sheet

- Other Wire Mesh Products

-

Metal Fence

- News

- About Us

- Contact Us

search