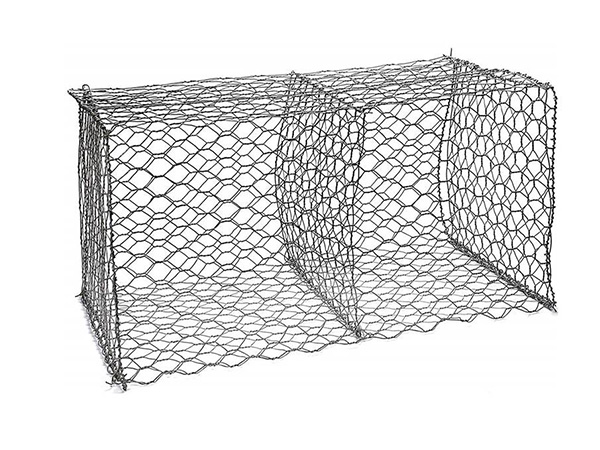

Hexagonal Mesh Gabion

Gabions are a estabIished, sturdy and technically proven way for erosion control and retention of earth. Gabions strength comes from a double twisted hexagonal mesh of steel wires, thus in the event of accidental damage or break of one or more wires, the double twisted wire configuration ensures that minimal strength reduction occurs.

Standards & Common Specifications

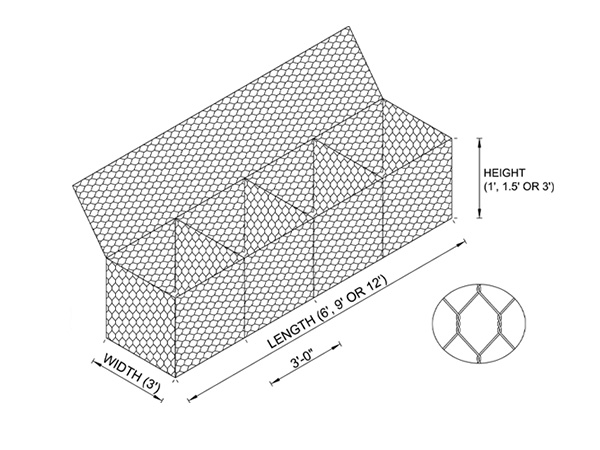

Gabion mesh is available in a variety of different specs, including wire thickness, opening size, box dimension and material grade. Consisting of hexagonal wire mesh, gabion box is divided into cells with diaphragms in 1 meter or 3ft intervals. The diaphragm reinforces the structures of gabion box.

We follow the major international standard in our manufacturing process.

Standard

The basic raw material is low carbon steel wire drawn from wire rod. As per customers’ requirements, wire will be galvanized or coated with PVC before weaving. Different material grade decides the quality of hexagonal mesh significantly. We have the following wire quality available in our production.

- ASTM Standard

- A975 - 11 Standard Specification for Double–Twisted Hexagonal Mesh Gabions and Revet Mattresses

- A641 / A641M - 09a Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire

- A856 / A856M - 03 Standard Specification for Zinc-5% Aluminum-Mischmetal Alloy-Coated Carbon Steel Wire

- BS Standard

- BS EN 10223-2 Steel wire and wire products for fencing and netting - Part 2: Hexagonal steel wire netting for agricultural, insulation and fencing purposes

- BS EN 10223-3 Steel Wire And Wire Products For Fencing And Netting - Part 3: Hexagonal Steel Wire Mesh Products For Civil Engineering Purposes

- BS EN 10244-2 Steel wire and wire products. Non-ferrous metallic coatings on steel wire. Zinc or zinc alloy coatings

- Our Tolerance Standard: on the hexagonal double-twisted wire mesh, size of opening should not exceed ± 5% on the nominal dimension.

- Galfan Coated Gabion Box with PVC Coated

- Colour: grey-RAL 7037, according to ASTM D2244 - 16.

- Specific weight: between 1.30 and 1.35 dN/dm3, according to ASTM D792 - 13.

- Hardness: between 50 and 60 Shore D, according to ASTM D2240 - 15e1.

- Tensile strength: not less than 210 dN/cm2, according to ASTM D412 - 16.

- Elongation: between 200% and 280%, according to ASTM D412 - 16.

- Weight loss: less than 5% after 24 hours at 105 °C, according to ASTM D2287 - 12.

- Residual ashes: less than 2%, according to ASTM D2124 - 99.

- Artificial ageing tests

- Salt spray test: test period 1500 hours, test method ASTM B117 - 16.

- Exposure to UV rays: test period 2000 hours at 63 °C, test method ASTM D1499 - 13 and ASTM G152 - 13 apparatus type E; exposure to high temperatures: test period 24 hours at 105 °C, test method ASTM D1203 - 16 and ASTM D2287 - 12.

Hexagonal Wire Mesh Regular Sizes

| Item |

Materials |

| Galvanized |

PVC Coated |

| Mesh (mm) |

60 × 80, 80 × 100, 100 × 120 |

60 × 80, 80 × 100, 100 × 120 |

| Mesh Wire (mm) |

2.2/2.7/3.0/3.2/3.7 |

2.2/2.7/3.0/3.2/3.7 |

| Selvedge Wire (mm) |

3.0/3.4/3.8 |

3.0.3.4,3.8 |

| Lacing Wire (mm) |

2.2 |

2.2 |

Gabion Box Regular Sizes

| Length |

Width |

Height |

Cell Nos |

Volume |

| m |

m |

m |

pcs |

CBM |

| 2 |

1 |

1 |

2 |

2 |

| 3 |

1 |

1 |

3 |

3 |

| 4 |

1 |

1 |

4 |

4 |

| 2 |

1 |

0.5 |

2 |

1 |

| 3 |

1 |

0.5 |

3 |

1.5 |

| 4 |

1 |

0.5 |

4 |

2 |

| 2 |

1 |

0.3 |

2 |

0.6 |

| 3 |

1 |

0.3 |

3 |

0.9 |

| 4 |

1 |

0.3 |

4 |

1.2 |

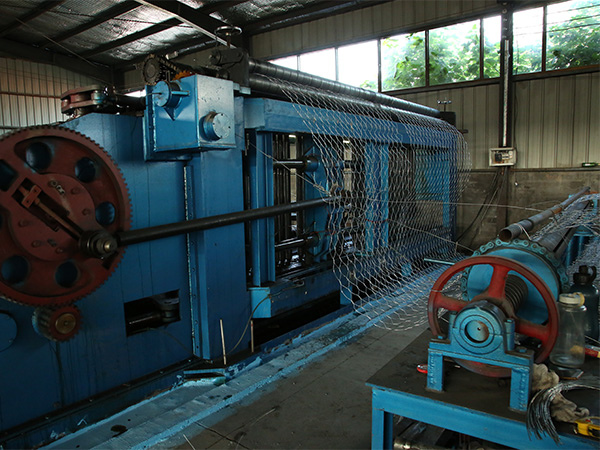

Machine

In our 11000 sqm gabion production workshop, Enzar Metal has 6 sets of advanced machines for gabion mesh weaving. All our machines are in good condition and efficient. We can deliver 150 tons of gabion mesh within a week time. Urgent order request will be proper treated in our production arrangement.

Packing and Loading

For easy handling and transportation, gabion box is usually shipped in bundle. The gabion box is folded and pressed into bundle, and then strapped with steel or nylon bandage. In this way, the gabion box package is in smallest dimension with suitable unit weight. Gabion is usually fitted into 40ft container to maximize the freight cost.

Installation Guideline

The installation is relatively easy then other similar material. It is briefly introduced as the following steps. For more installing and designing, please send inquiry for detailed documents.

- Step #1: Assembly Unpack the gabion bundles → Unfold each gabion panel → Fold to form a regular box → Lace at the selvage wire with binding wire provided

- Step #2: Forming the Structure Level the working ground → Carry and place the gabion as designed → Wire up the gabions aside

- Step #3: Stretching gabions before filling Place the stretching bars at each corner → Fix the bars to stretch the gabion → Check the wiring after Stretching

- Step #4: Filling rocks Fill the gabion by rocks with proper sizes → Level the rocks surface in the gabion → Close and secure the lid by binding wire provided

General Assortments and Applications

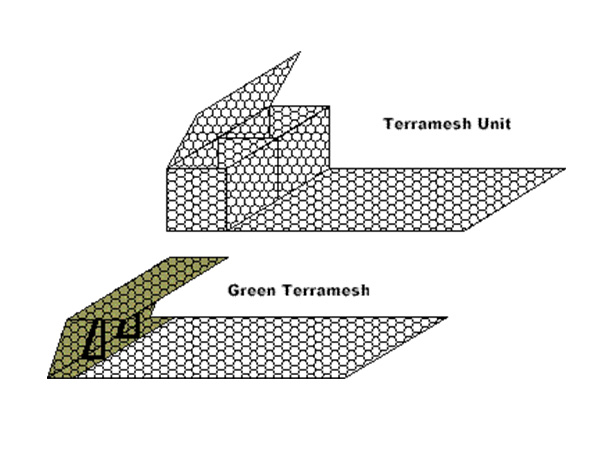

Reno Mattress

Reno Mattress is a typical gabion box used for riverbank protection. The thickness/height is less than 500mm compared with normal gabion box.

Terra Mesh

This type is particularly applied as slope forming. Faced by gabion and reinforced by roll mesh, terra mesh gives the slope project firm soil stabilization property.